Email: james.yu@unisn.com.cn

Phone: +86 028-81726336

Edge banding not only enhances the aesthetic appeal of products but also effectively seals harmful substances within the boards, playing an environmentally-friendly role.

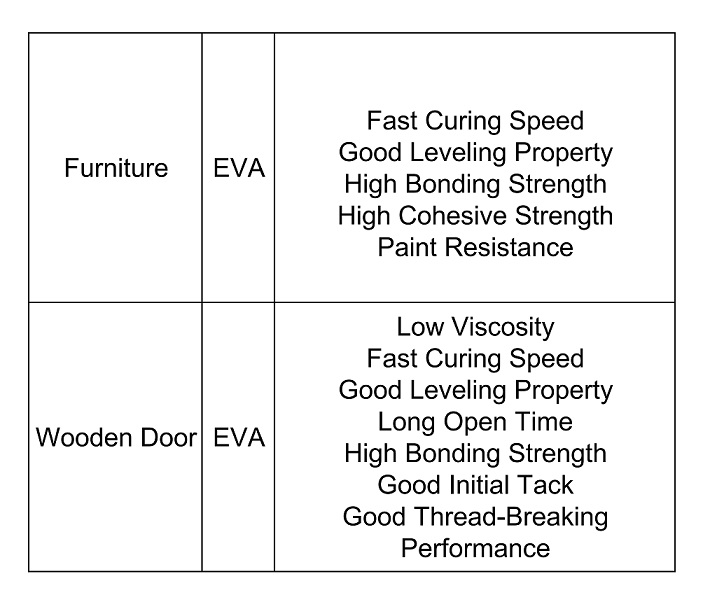

•Applicable Edge-banding Substrates: Particleboard, medium-density fiberboard, solid wood.

•Applicable Edge-banding Materials: PVC edge-banding, wood veneer, and melamine-based edge-banding.

Advantages:

Low Viscosity: Excellent fluidity, glue-saving, and suitable for automated lines. In molten state, it has strong fluidity and can be evenly applied. It uses less glue than high-viscosity alternatives while achieving the same bonding effect.

Fast Curing Speed: Improves bonding efficiency and adapts to mass production. After application, the hot melt glue achieves initial fixation in seconds, avoiding edge banding displacement or peeling caused by slow curing.

Good Leveling Property: Spreads quickly and evenly after application, without shrinkage cavities, glue accumulation or glue breakage, suitable for straight/irregular edge banding without manual correction; the glue layer is smooth and continuous without bubbles before curing, leveling accurately only in the bonding area without glue overflow or stringing; after curing, the glue layer has a consistent thickness, no glue lines or steps, firm bonding, and resistance to temperature changes and cracking.

Long Open Time: High operational fault tolerance, suitable for complex processes. After gluing, there is ample time to adjust the position of the edge banding strip and correct fitting deviations without rushing for curing; especially suitable for irregular edge banding, manual edge banding or material change scenarios on assembly lines, avoiding bonding misalignment or peeling caused by rapid curing, and ensuring edge banding accuracy and bonding quality.

High Bonding Strength: Stable connection without detachment, impact resistance, and aging resistance. After curing, the hot melt glue forms a high-strength bond with the edge banding and substrates; during peeling, the filter medium breaks while the glue layer remains intact.

Good Initial Tack: Instant fixation, reducing auxiliary operations. It generates tack immediately after application, avoiding interface detachment due to poor initial tack.

Good Thread-Breaking Performance: Optimizes operational experience and avoids contamination. When pausing or switching substrates during edge banding, the hot melt glue rarely leaves residual stringing. No excess glue threads wrap around equipment or adhere to product surfaces, preventing product contamination or appearance damage.

High Cohesive Strength: Ensures transportation durability, impact resistance, and aging resistance. The cured glue layer has high inherent strength, resisting failure from external stretching or environmental changes. It can withstand impact force from extrusion and jolting, avoiding glue layer rupture and peeling.

Paint Resistance: Resistant to coating erosion, suitable for subsequent painting processes. After curing, the glue layer does not chemically react with paint or coatings, and will not swell, soften or peel off during painting (spraying or brushing).

Where is it used?

The "UNISN" hot melt glue for edge banding is mainly used in edge - banding machines. The edge-banding machine liquefies the edge banding adhesive and applies it to the board to be edge-banded. Then, the board is pressed together with the edge-banding material. After the liquid edge banding glue cools and solidifies, the board and the edge-banding material are bonded together.

Who uses it?

•Furniture manufacturer

•Wood door manufacturers

•And more

How to use?

Usage and Precautions

•Low - Temperature Edge-banding Hot-melt Adhesive: Mainly used in manual edge-banding machines. The recommended operating temperature range is 130 - 160°C.

•Medium - Temperature Edge-banding Hot-melt Adhesive: Suitable for manual or semi-automatic edge-banding machines. The operating temperature is set between 160 - 190°C.

Why Choose UNISN

•Fine and Uniform Glue Lines: It can form a neat and smooth glue layer on the edge of the wooden board, enhancing the product's grade.

•Good Fluidity: It can be quickly and evenly coated on the surface of the adherend and fit well, ensuring the integrity of the bond.

•High Peel Strength: It creates a strong adhesive force between the hot-melt adhesive, the wooden board, and the edge-banding strip, effectively withstanding various external forces such as pulling, collision, and friction that may occur during daily use.

•Excellent High and Low - Temperature Resistance: In high-temperature environments, the hot-melt adhesive will not soften or flow due to heat, causing the edge-banding strip to shift or the glue layer to lose its adhesion. In low-temperature environments, it will not become brittle, resulting in glue-layer cracking or edge-banding strip detachment.