Email: james.yu@unisn.com.cn

Phone: +86 028-81726336

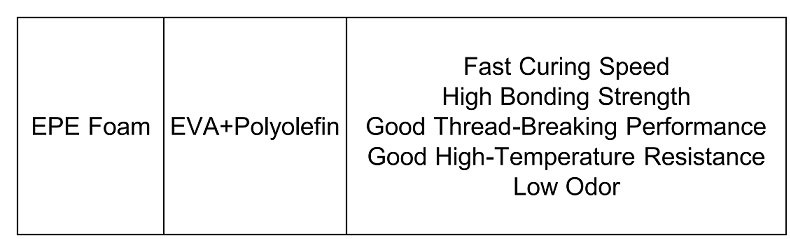

What is hot melt adhesive for Foam Packaging?

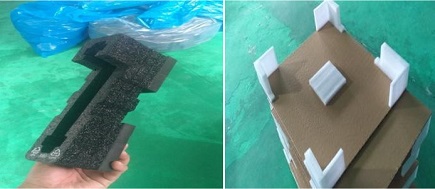

EPE Foam is a new type of environmentally friendly packaging material. It can effectively absorb impact forces and plays a good protective role for fragile and vulnerable items. Hot melt adhesive manufacturers provide eva hot melt adhesive or polyolefin hot melt adhesive for foam to foam and eva foam sealing.

Advantages:

Fast Curing Speed: Improves bonding efficiency and adapts to mass production. After application, the hot melt adhesive achieves initial fixation in seconds, avoiding assembly displacement or debonding caused by slow curing.

High Bonding Strength: Stable connection without detachment, impact resistance, and aging resistance. After curing, the hot melt adhesive forms a high-strength bond with the mattress fabric; during peeling, the filter medium (mattress fabric) breaks while the adhesive layer remains intact.

Good Thread-Breaking Performance: Optimizes operational experience and avoids contamination. When pausing or switching substrates during bonding, the hot melt adhesive rarely leaves residual stringing. No excess adhesive threads wrap around equipment or adhere to product surfaces, preventing product contamination or appearance damage.

Good High-Temperature Resistance: Adapts to extreme storage environments for long-term stability. It can withstand high temperatures, and the adhesive layer will not soften or flow when exposed to prolonged high-temperature conditions. When products are stored in high-temperature warehouses or transported outdoors in summer, the bonded areas remain firmly attached, preventing debonding due to high-temperature aging—especially suitable for customers in high-temperature regions.

Low Odor: Compliant with environmental standards and suitable for clean scenarios. The hot melt adhesive features a low-VOC formula, releasing almost no odor during curing. It does not irritate operators in the assembly workshop or contaminate mattress fabric; finished mattresses have no residual adhesive odor. No odor is generated from adhesive layer decomposition during long-term use.

Who uses it?

•Packaging manufacturer

•Electronics and electrical appliances manufacturers

•And more

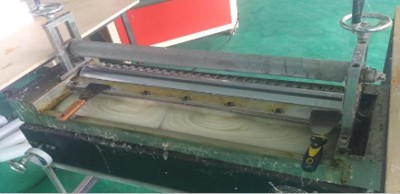

How to use?

Usage and Precautions

Why choose UNIS?

•Low Odor: Reduces the impact of pungent odors on the health of operators and prevents the transfer of the packaging material's odor to the product.

•Good High - Temperature Resistance: It can still maintain good bonding strength and stability in a certain high - temperature environment, making it suitable for high - temperature applications.