Email: james.yu@unisn.com.cn

Phone: +86 028-81726336

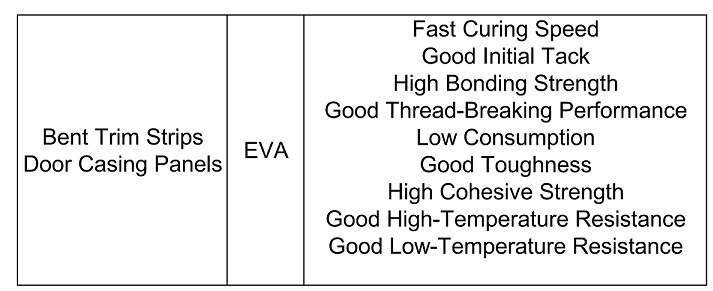

Hot melt adhesives for woodworking are a category of hot melt adhesives specifically designed for wood processing scenarios. They are primarily based on thermoplastic polymers, exist as solids at room temperature, are applied after being melted by heating, and form bonds upon cooling. They are widely used in woodworking processes such as furniture manufacturing, board splicing, bending, and veneering.

Advantages:

Fast Curing Speed: Improves bonding efficiency and suits mass production. The hot melt adhesive achieves initial fixation within seconds after application, preventing assembly displacement or debonding caused by slow curing.

Good Initial Tack: Instant fixation, reducing auxiliary operations. It generates tack immediately after application, avoiding interface detachment due to poor initial tack.

High Bonding Strength: Stable connection without detachment, impact and aging resistance. After curing, the hot melt adhesive forms a high-strength bond with mattress fabric; during peeling, the filter medium (mattress fabric) breaks while the adhesive layer remains intact.

Good Thread-Breaking Performance: Optimizes operational experience and avoids contamination. When pausing or switching substrates during bonding, the hot melt adhesive rarely leaves residual stringing. No excess adhesive threads wrap around equipment or adhere to product surfaces, preventing product contamination or appearance damage.

Low Consumption: Firm bonding can be achieved with thin coating, using less adhesive for the same effect; no waste from adhesive overflow or stringing, and automated production lines can precisely control dosage, reducing raw material and cleaning costs.

Good Toughness: Suitable for irregular bending; the adhesive layer deforms synchronously with materials without brittleness or delamination. It buffers stress during long-term use, preventing veneer warping and debonding, and withstands repeated bending adjustments.

High Cohesive Strength: Ensures transportation durability, impact and aging resistance. The cured adhesive layer has high inherent strength, resisting failure from external stretching or environmental changes. It can withstand impact from extrusion and jolting, avoiding adhesive layer rupture and debonding.

Good High-Temperature Resistance: Adapts to extreme storage environments for long-term stability. It can withstand high temperatures; the adhesive layer does not soften or flow in prolonged high-temperature conditions. When products are stored in high-temperature warehouses or transported outdoors in summer, bonded areas remain firm, preventing debonding due to high-temperature aging—especially suitable for customers in high-temperature regions.

Good Low-Temperature Resistance: Breaks low-temperature limitations for worry-free winter use. It maintains good molten fluidity and bonding activity in low-temperature environments. During assembly in low-temperature regions, the adhesive bonds quickly after application, and the cured adhesive layer does not become brittle; bonding strength remains unchanged when products are stored in low-temperature warehouses or transported in winter.

Where is it used?

The "UNISN" hot - melt adhesive for bent moldings is mainly applied to the spray - bonding of solid wood boards, multi - layer solid wood boards, and clips during the production of door casing moldings by wooden furniture manufacturers.

Who uses it?

•Furniture manufacturer

•Wood door manufacturer

•Wood board manufacturer

•And more

How to use?

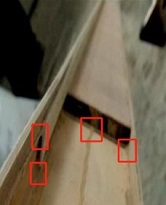

Most production lines are equipped with one large and one small glue - melting tank. The large glue - melting tank supplies glue to the spray - bonding lines on both sides for bending, while the small glue - melting tank is used for bonding the bottom of the core board and the clips. A few production lines are equipped with two small glue - melting tanks or only one large glue - melting tank.

Spray bonding between solid wood boards and multi - layer solid wood boards.

Spray bonding between multi - layer solid wood boards and clips.

Usage and Precautions

•Note: In cold environments, the hot - melt adhesive dissipates heat quickly, and the operating temperature of the hot - melt adhesive needs to be increased by at least 5°C.

In addition, note the following:

Why choose UNISN?

•Fast Melting Speed: It can transform from a solid state to a liquid state in a relatively short time, enabling quick use and improving production efficiency.

•Good Fluidity: It can be quickly and evenly coated on the surface of the adherend and fit well, ensuring the integrity of the bond.

•Fast Curing Speed: It allows the adherends to be fixed rapidly, greatly shortening the production cycle.

•High Bonding Strength: It has good bonding performance with various types of wood, ensuring that the bonded objects will not easily fall off or separate.

•Good High - Temperature Resistance: It can still maintain good bonding strength and stability in a certain high - temperature environment, making it suitable for high - temperature applications.