Email: james.yu@unisn.com.cn

Phone: +86 028-81726336

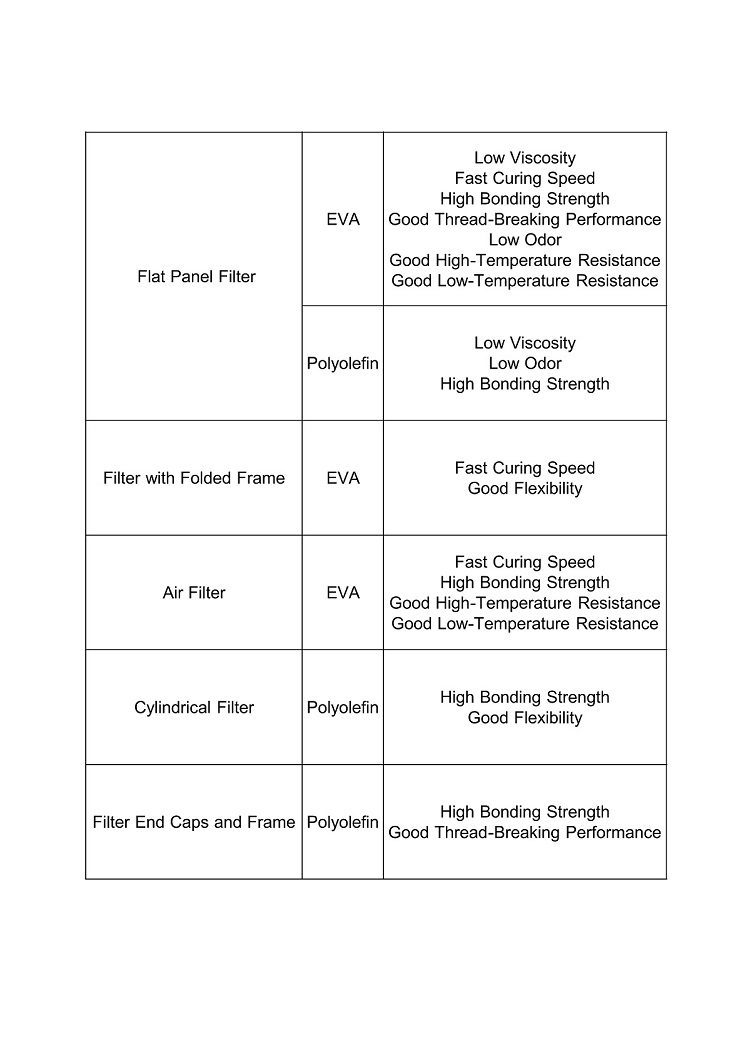

The hot melt adhesive for air filters is a type of hot-melt adhesive specifically designed to meet the bonding needs of various components in the production process of air purifiers, belonging to the category of thermoplastic adhesives. It is applied after being melted by heating and can quickly solidify to form a bonding effect upon cooling. It features solvent-free properties, good environmental friendliness, and convenient operation, making it suitable for bonding scenarios involving the complex internal structures of air purifiers. According to specific bonding requirements, hot melt adhesives for air purifiers can be divided into EVA hot melt adhesives and polyolefin hot melt adhesives.

Advantages:

Low Viscosity: Excellent fluidity, glue-saving, and suitable for automated lines. With strong fluidity, it enables uniform application without clogging equipment; it uses less glue than high-viscosity alternatives while achieving the same bonding effect. This not only reduces costs but also prevents excessive glue overflow from contaminating products

Fast Curing Speed: Improves bonding efficiency and adapts to mass production. After application, the hot melt glue achieves initial fixation in seconds, avoiding assembly displacement or peeling caused by slow curing.

High Bonding Strength: Stable connection without detachment, impact resistance, and aging resistance. After curing, the hot melt glue forms a high-strength bond with the filter medium and frame of the filter; during peeling, the filter medium breaks while the glue layer remains intact.

Good Thread-Breaking Performance: Optimizes operational experience and avoids product contamination. When the glue gun pauses or switches substrates during assembly, the hot melt glue rarely leaves residual threads. No excess glue threads wrap around equipment or adhere to product surfaces, preventing product contamination or appearance damage.

Good High-Temperature Resistance: Adapts to extreme storage environments for long-term stability. It can withstand high temperatures, and the glue layer will not soften or flow when exposed to prolonged high-temperature conditions. When products are stored in high-temperature warehouses or transported outdoors in summer, the bonded areas remain firmly attached, preventing peeling due to high-temperature aging—especially suitable for customers in high-temperature regions.

Good Low-Temperature Resistance: Breaks low-temperature limitations for reliable winter use. It maintains good molten fluidity and bonding activity in low-temperature environments. During assembly in low-temperature regions, the glue bonds quickly after application, and the cured glue layer does not become brittle; the bonding strength remains unchanged when products are stored in low-temperature warehouses or transported in winter.

Low Odor: Compliant with environmental standards and suitable for clean scenarios. The hot melt glue features a low-VOC formula, releasing almost no odor during curing. It does not irritate operators in the assembly workshop or contaminate filter media; finished filters have no residual glue odor. No odor is generated from glue layer decomposition during long-term use.

Good Flexibility: Suitable for irregular-shaped bonding, bending resistance, cracking resistance, and long-term stability. After curing, the glue layer has good flexibility and can bend with slight deformation of the filter medium and frame. When bonding irregular structures, the glue layer closely fits curved surfaces, avoiding bonding gaps and improving sealing performance.

Where is it used?

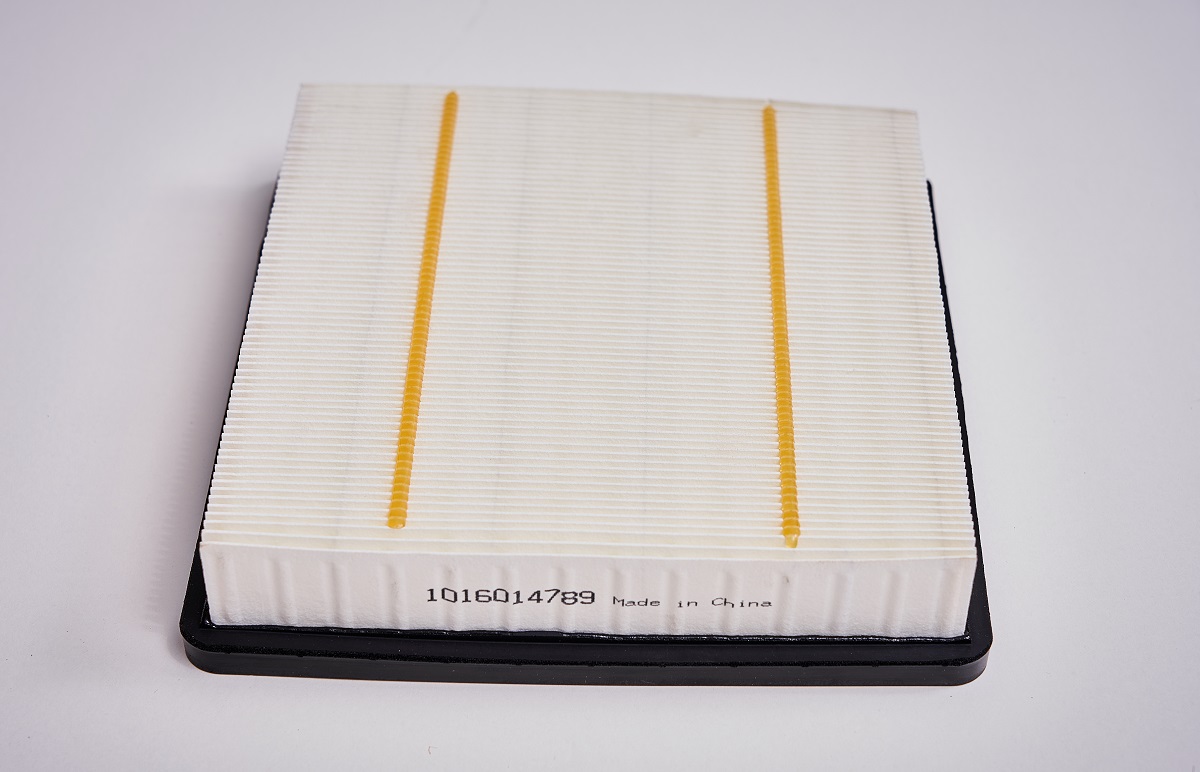

Bonding of filters and frames: Adhere HEPA filters, activated carbon filters, pre-filters, etc., to the edges of plastic or metal frames to ensure a tight seal between the filters and the frames. This prevents unfiltered air from leaking through gaps and guarantees the purification effect.

Fixing of multi-layer filter stacks: Some air purifiers adopt a multi-layer composite filter design. Hot melt adhesive can be used to bond the edges between layers, preventing the filters from shifting or separating during the operation of the device.

•Air filter manufacturer

•Water filter manufacturer

•Automotive filter manufacturer

•And more

Bonding of filter screens and frames

Positioning: Fix the filter screens and frames on the tooling fixtures via an automated assembly line to ensure the bonding edges are aligned.

Gluing:

For frame gluing: The spray head moves at a constant speed along the inner edge of the frame, extruding a continuous glue line (or dotted glue), avoiding glue overflow that might contaminate the effective filtering area of the filter screen.

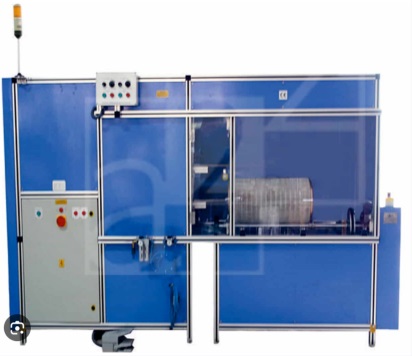

For filter edge gluing: For flexible filter screens, roller gluing is adopted. The molten glue is evenly transferred to the edge of the filter screen through the glue roller, and then bonded with the frame.

Pressing and curing: Immediately press the filter screen and frame together after gluing, and use natural cooling (or air-cooling assistance) to cure the glue layer, forming a sealed bond.

Fixing of multi-layer filter stacks

Layer alignment: Stack multiple layers of filter materials in sequence, align the edges, and fix them.

Local gluing: Apply glue dots at the four corners of the interlayer edges of the filter screens or every few centimeters, or coat thin glue lines along the edges, ensuring firm bonding without blocking the pores of the filter materials.

Curing: Lightly press the stacked layers to allow the glue layer to cure quickly, preventing interlayer displacement.

Usage and Precautions

Maintenance Recommendations

Weekly: Check connections. Inspect the compressed air filter bowl. Drain adhesive residue. Quarterly: Drain adhesive to remove carbon deposits from the manifold.

Biannually: Inspect/replace the filter screen.

As Needed: Replace the spray gun body, nozzle, and filter screen, and clean the adhesive machine.

Precautions

1.Do not exceed 180°C when heating.

2.Avoid mixing different types of hot melt adhesives.

3.Wear gloves and safety goggles or a face shield when adding adhesive or performing maintenance.

4.Add materials carefully to prevent splashing and burns.

5.Maintain proper adhesive levels to avoid splashing during refilling.

6.Keep a bucket of cold water nearby for immediate treatment in case of burns.

7.Position the adhesive machine and related equipment below eye level.

Why Choose UNISN

•Fast Melting Speed: It can transform from a solid state to a liquid state in a relatively short time, allowing it to be used quickly and improving production efficiency.

•Good Fluidity: It can be quickly and evenly coated on the surface of the adherend and fit well, ensuring the integrity of the bond.

•Fast Curing Speed: It enables the adherends to be fixed quickly, greatly shortening the production cycle.

•High Bonding Strength: It has good bonding performance with a variety of materials, ensuring that the bonded objects will not easily fall off or separate.

•Good Anti - brittleness Property: Under the long - term influence of external forces during the use of the mattress, it can maintain good flexibility and bonding strength, and is not prone to brittle fracture or glue - off.

•Good High - Temperature Resistance: In a certain high - temperature environment, it can still maintain good bonding strength and stability, making it suitable for high - temperature environments.

•Environmentally Friendly and Harmless: It is made from environmentally friendly raw materials, causing no pollution to human health and the environment. It can be widely used in fields with high environmental requirements.