Email: james.yu@unisn.com.cn

Phone: +86 028-81726336

What is hot melt adhesive for matters?

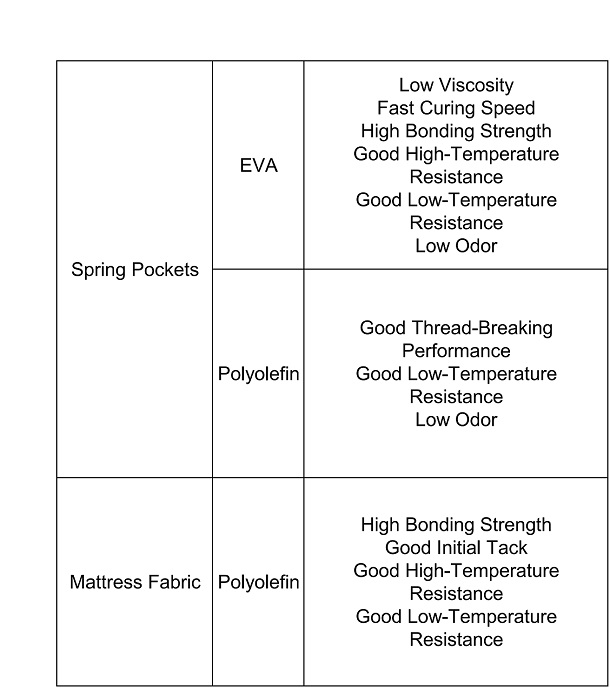

The hot melt glue used in mattress production is a type of fabric bonding material specifically designed for bonding components such as mattress fabrics, fillers, and pocket springs. Its core feature is that it is applied after being melted by heating, then quickly solidifies and bonds upon cooling. It contains no solvents, offering strong environmental friendliness and ease of operation. It's a hot gule for fabric to fabric.

Advantages:

Low Viscosity: Excellent fluidity, glue-saving, and suitable for automated lines. It has strong fluidity in the molten state and can be evenly applied easily. It uses less glue than high-viscosity adhesives while achieving the same bonding effect.

Fast Curing Speed: Improves bonding efficiency and adapts to mass production. After application, the hot melt adhesive achieves initial fixation in seconds, avoiding assembly displacement or debonding caused by slow curing.

High Bonding Strength: Stable connection without detachment, impact resistance, and aging resistance. After curing, the hot melt adhesive forms a high-strength bond with the mattress fabric; during peeling, the filter medium (mattress fabric) breaks while the adhesive layer remains intact.

Good Initial Tack: Instant fixation, reducing auxiliary operations. It generates tack immediately after application, avoiding interface detachment due to poor initial tack.

Good Thread-Breaking Performance: Optimizes operational experience and avoids contamination. When pausing or switching substrates during bonding, the hot melt adhesive rarely leaves residual stringing. No excess adhesive threads wrap around equipment or adhere to product surfaces, preventing product contamination or appearance damage.

Good High-Temperature Resistance: Adapts to extreme storage environments for long-term stability. It can withstand high temperatures, and the adhesive layer will not soften or flow when exposed to prolonged high-temperature conditions. When products are stored in high-temperature warehouses or transported outdoors in summer, the bonded areas remain firmly attached, preventing debonding due to high-temperature aging—especially suitable for customers in high-temperature regions.

Good Low-Temperature Resistance: Breaks low-temperature limitations for worry-free winter use. It maintains good molten fluidity and bonding activity in low-temperature environments. During assembly in low-temperature regions, the adhesive bonds quickly after application, and the cured adhesive layer does not become brittle; the bonding strength remains unchanged when products are stored in low-temperature warehouses or transported in winter.

Low Odor: Compliant with environmental standards and suitable for clean scenarios. The hot melt adhesive features a low-VOC formula, releasing almost no odor during curing. It does not irritate operators in the assembly workshop or contaminate mattress fabric; finished mattresses have no residual adhesive odor. No odor is generated from adhesive layer decomposition during long-term use.

The "UNISN" mattress fabric bonding adhesive is mainly used to tightly connect components such as the mattress fabric with the internal pocket spring and between pocket spring.

Who uses it?

Mattress manufacturer.

How to use?

•Mattress Adhesive Coating Machine: This equipment first heats and melts solid hot – melt adhesive into a liquid state, and then uses a pressure device to transport the liquid hot – melt adhesive to the coating head.

•Equipment heating: Load the hot melt adhesive sticks into the glue gun or melting tank, heat to the specified temperature, and wait until the adhesive is completely melted into a fluid state.

Usage and Precautions

•Open Time: 10 - 20 seconds

•Operating Temperature Settings: Glue melting tank: 160 - 190°C; Hose and spray gun: 150 - 180°C. Note: In cold environments, the hot - melt adhesive dissipates heat quickly, and the operating temperature of the hot - melt adhesive needs to be increased by at least 5°C.

In addition, note the following:

1.Pre - heat the glue - melting device for about 2 hours first.

2.Control the amount of glue added according to the production volume to prevent over - heating due to incomplete consumption over a long period, which may cause the glue to age and affect its adhesion. Also, avoid insufficient consumables, which may affect glue spraying.

3.After replenishing consumables, reseal the packaging bag and cover the glue - melting tank to prevent impurities from mixing in and blocking the hose and spray gun.

4.The use place should be well - ventilated and kept away from open flames.

5.Since the glue - melting tank and the glue - spraying system are at high temperatures, safety protective equipment must be worn during operation to prevent burns.

6.Avoid contact between the melted glue and parts such as eyes and skin.

7.If the melted glue comes into contact with the skin, immediately immerse the affected skin in cold water and rinse for at least 10 minutes. Seek medical treatment in a timely manner after cooling.

Why Choose UNISN

•Fast Melting Speed: It can transform from a solid state to a liquid state in a relatively short time, allowing it to be used quickly and improving production efficiency.

•Good Fluidity: It can be quickly and evenly coated on the surface of the adherend and fit well, ensuring the integrity of the bond.

•Fast Curing Speed: It enables the adherends to be fixed quickly, greatly shortening the production cycle.

•High Bonding Strength: It has good bonding performance with a variety of materials, ensuring that the bonded objects will not easily fall off or separate.

•Good Anti - brittleness Property: Under the long - term influence of external forces during the use of the mattress, it can maintain good flexibility and bonding strength, and is not prone to brittle fracture or glue - off.

•Good High - Temperature Resistance: In a certain high - temperature environment, it can still maintain good bonding strength and stability, making it suitable for high - temperature environments.