Email: james.yu@unisn.com.cn

Phone: +86 028-81726336

What is lubricant for chain conveyor?

Water-based lubricants are spray-type lubricants formulated by compounding surfactants such as amine salts or polyesters. They possess lubricating, bacteriostatic, and cleaning functions, and can effectively act between the surface of the chain and the can body. They reduce the friction between the chain and the bottom of the can, prevent can/bottle inversion and shaking, reduce the wear of the conveying chain, clean the dirt on the chain plates, and improve production efficiency. They are widely applicable to high-speed canning lines for beer, beverages, milk, etc.

Who uses it?

•Beverages manufacturer

•Beer manufacturer

•And more.

How to use?

Use of Pumps

1.Hydrodynamic proportional pump

2.Electronic diaphragm flow pump

When switching product types, turn off the electronic diaphragm pump to avoid air intake. If air is drawn in, increase the frequency to force pumping; if this fails, bleed the air.

Usage and Precautions

Why choose UNISN?

1.

The product is green and environmentally friendly, non-toxic and odorless, and

will not block the spray pipe after long-term use. It has a high dilution ratio

(with a usage concentration of 1:100-500).

2. It has excellent lubricating performance, which can effectively reduce the

friction coefficient and meet the lubrication requirements of the production

line.

3.

It will not corrode labels or cause contamination and damage to products during

production.

4. The product has low foam, is not easy to splash, and keeps the production

site clean and hygienic.

5. It has certain bacteriostatic, bactericidal and chain-cleaning functions.

6. It does not corrode the chain plates, reduces chain plate wear and lightens the friction load on the chain plates. It also has good anti-rust performance. Due to the special anti-rust substances contained in its formula, the iron parts of the filling equipment can be protected from rust by this lubricant, thereby prolonging the service life of the equipment.

7. It has no pungent smell or gas, is environmentally friendly and pollution-free, and has good stability. It will not deteriorate even after long-term use and storage.

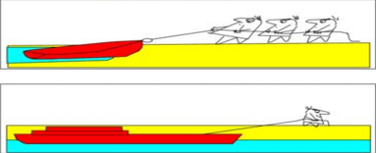

The principle of lubrication is to provide a friction-reducing oil film for sliding loads.