Email: james.yu@unisn.com.cn

Phone: +86 028-81726336

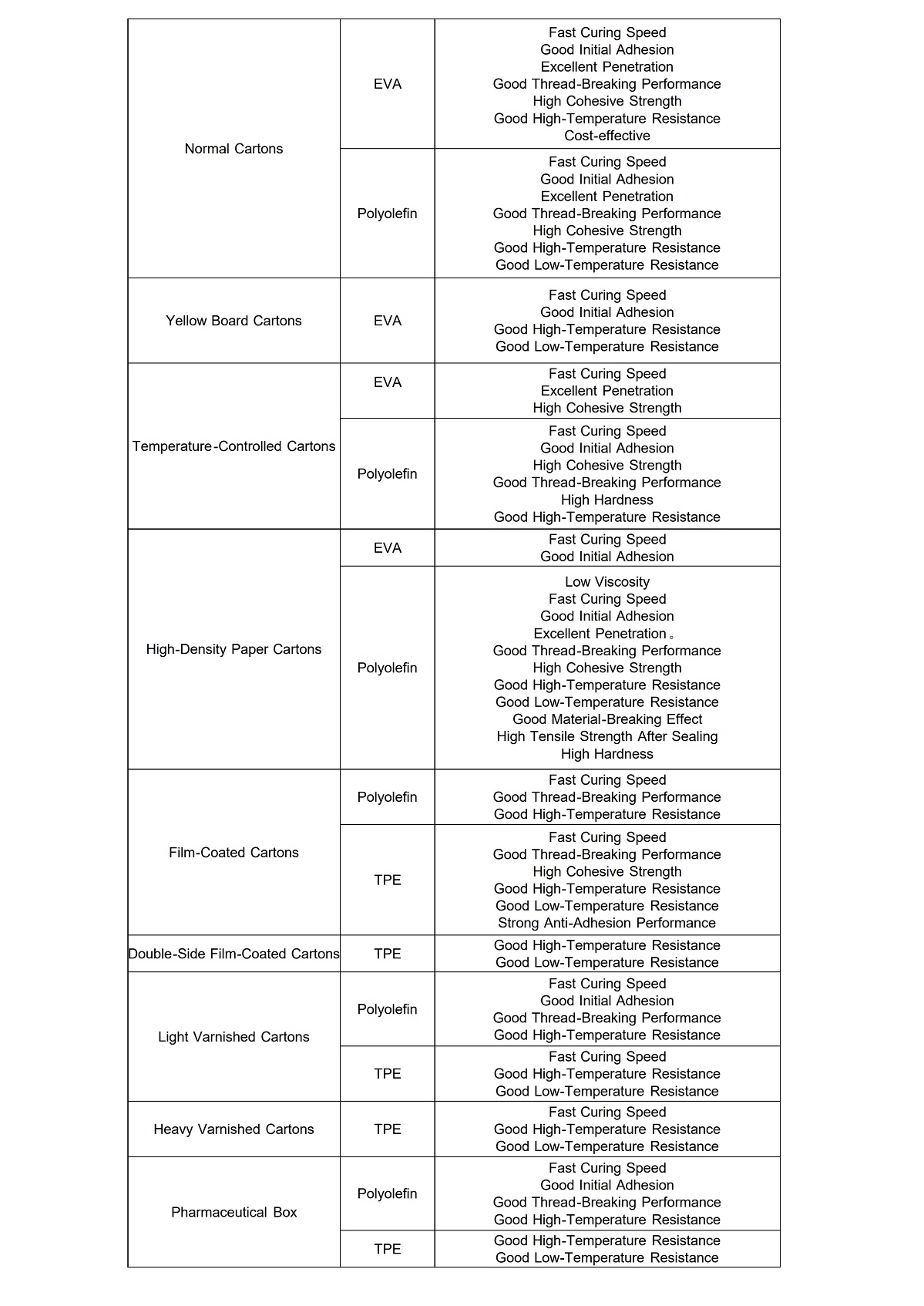

Using hot melt glue as the bonding and sealing material for sealing cardboard boxes is a packaging method. It ensures a strong bond, preventing the boxes from splitting during transportation and storage. The quick setting time enhances packaging efficiency, making it suitable for large-scale automated packaging production lines. The main type are eva hot melt adhesive, polyolefin glue, and TPE glue.

Advantages:

Low Viscosity: Excellent fluidity, glue-saving, and suitable for automated lines. The glue can quickly pass through nozzles to form even glue strips without clogging equipment; it uses less glue than high-viscosity alternatives while achieving the same bonding effect. This not only reduces costs but also prevents excessive glue overflow from contaminating cartons.

Fast Curing Speed: Improves carton sealing efficiency and adapts to mass production. After application, the hot melt glue achieves initial fixation in seconds, avoiding carton displacement or peeling caused by slow curing.

Good Initial Adhesion: Instant fixation with minimal auxiliary operations. It generates adhesion immediately after application, preventing carton seam detachment due to poor initial stickiness.

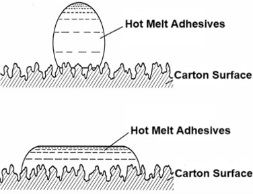

Excellent Penetration: Enhances bonding stability and adapts to different paper types. In molten state, the glue quickly penetrates into the gaps of paper fibers, forming a firm bond between the surface and the paper core. This reduces carton seam cracking during transportation caused by jolting.

Good Thread-Breaking Performance: Optimizes operational experience and avoids packaging contamination. When the glue gun pauses or switches cartons, the EVA hot melt glue rarely leaves residual threads. No excess glue threads wrap around equipment or adhere to carton surfaces, preventing product contamination or appearance damage.

High Cohesive Strength: Ensures transportation durability, impact resistance, and aging resistance. The cured glue layer has high inherent strength, resisting failure from external stretching or environmental changes. During carton stacking or long-distance transportation, the sealed seams can withstand pressure and impact from jolting, avoiding glue layer rupture and peeling.

High Hardness: Enhances glue layer support, resisting deformation and cracking. The cured glue layer is harder than EVA and other types of hot melt glue, preventing deformation under pressure. When cartons are stacked, the glue layer at sealed seams can withstand the weight of upper cartons, avoiding seam deformation and opening; it resists damage from collisions and friction during long-distance transportation.

Good High-Temperature Resistance: Adapts to extreme storage environments for long-term stability. It can withstand high temperatures, and the glue layer will not soften or flow when exposed to prolonged high-temperature conditions. When cartons are stored in high-temperature warehouses or transported outdoors in summer, the sealed seams remain firmly bonded, preventing peeling due to high-temperature aging—especially suitable for customers in high-temperature regions.

Good Low-Temperature Resistance: Breaks low-temperature limitations for reliable winter use. It maintains good molten fluidity and bonding activity in low-temperature environments. During sealing in low-temperature regions, the glue bonds quickly after application, and the cured glue layer does not become brittle; the bonding strength remains unchanged when cartons are stored in low-temperature warehouses or transported in winter.

Strong Anti-Adhesion Performance: No caking at high temperatures, ensuring convenient use. The base material of the hot melt glue results in extremely low surface viscosity at room temperature. Particles do not adhere to each other due to viscosity overflow, maintaining a loose state. After unpacking, the glue can be directly fed into glue machines without prior crushing or sorting, saving operational time.

Good Material-Breaking Effect: Achieves "paper layer breaks before glue layer" for more stable bonding. The bonding strength exceeds the tensile strength of paper fibers in ordinary cartons, causing the carton paper layer to tear (instead of glue layer detachment) during peeling. Violent tearing is required to open sealed cartons, and sealed seams cannot be easily peeled off; even when subjected to severe jolting during transportation, the glue layer will not separate from the carton.

High Tensile Strength After Sealing: Resists stretching and impact, suitable for heavy-load scenarios. The cured glue layer has high tensile strength and can withstand stress from external stretching and impact. For cartons loaded with heavy products, the sealed seams can bear the tensile force caused by product weight without cracking due to heavy loads; during long-distance transportation (e.g., sudden braking, jolting), the glue layer absorbs impact force to maintain the integrity of the seal.

Where is it used?

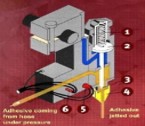

UNISN Carton Sealing Hot Melt Adhesives are primarily used in: The hot melt adhesive machine heats the solid cardboard adhesive to a molten state, then applies the liquid adhesive evenly to the carton's sealing flaps using a glue gun or nozzle. After closing the flaps, the adhesive cools and solidifies, creating a strong and secure seal.

Who uses it?

• Food and beverages manufacturer

• Packaging manufacturer

• And more.

How to use?

Usage and Precautions

As Needed: Replace the spray gun body, nozzle, and filter screen, and clean the adhesive machine.

Precautions

Why choose UNISN?

Comprehensive Product Range: Offers solutions tailored to different application environments and conditions, balancing quality and cost-effectiveness.

Viscosity: Adapts to various equipment for quick and even application, ensuring a complete bond.

Curing Speed: Matches the pressing cycle of equipment, enabling rapid fixation and significantly shortening production cycles.

High Bonding Strength: Provides excellent adhesion to various packaging materials, ensuring durability.

Temperature Resistance: Maintains strong bonding strength and stability across different temperature environments.

Cost-Effective: Delivers lower-cost solutions while meeting performance requirements.

Quality Assurance: Laboratory-tested under extreme conditions to ensure consistent and reliable quality.

Eco Friendly Adhesive: Made from environmentally safe materials, harmless to human health and the environment. Suitable for industries with high environmental standards.